Rope production methods

The first step is to prepare raw materials. First, the required raw materials are prepared and transported to the factory. After that, these materials are turned into rope strands with the help of an extruder, and these fibers are placed inside the rope production machine, so that after adjusting the machine according to the customer’s request, plastic rope in different sizes can be produced. This product can be produced in 2 ways:

- woven rope

-

twisted rope

woven rope

The woven rope consists of two parts, the rope cover and the rope core. This product can be produced with natural fibers and synthetic fibers and has the ability to be produced with several coatings. Compared to the woven rope, even if both products are made with the same type of raw materials, the woven method has a higher wear resistance. Keep in mind that the product produced in this method works more flexibly.

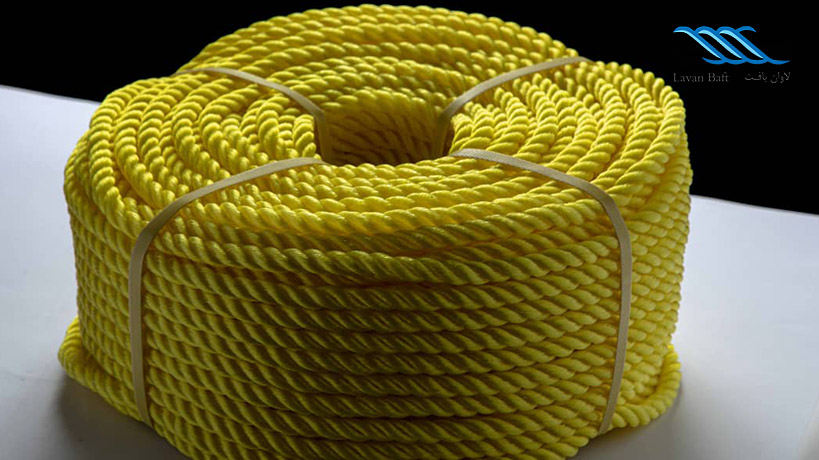

twisted rope

This product is made from two to four strands and can be produced with natural and synthetic fibers. Twisted rope has higher tensile strength compared to woven rope; For this reason, it is more durable and has a longer lifespan.

The size (diameter) of the rope

The size (diameter) of the rope is usually between 2 mm and 32 mm. As the diameter of the product increases, the weight of each meter increases. It should be noted that the number of threads used to produce this product increases exponentially. The length of this product ranges from 100 meters to 500 meters in one piece, so the increase or decrease of the length of the plastic rope depends on its size. As a result, the smaller the size of the product, the more space it occupies.

Notes on the rope production line

To set up and start a production line in all industries, including rope production, you must first estimate the cost. Then prepare the necessary capital and refer to experts and engineers in that field to get advice. It is better for producers to use expert forces to have the highest efficiency.

Things to consider for setting up a rope production line

- Have enough information about the specifications and how to connect machines and equipment.

- Choose the right layout to minimize the length of the production line.

- According to the type of operation of machines and equipment, combine them.

- Make enough space between equipment and machinery.

- Use the right architecture to communicate between equipment and machines.

- Check the infrastructure of the desired building.

The stages of setting up the rope production line

- The first step of equipment procurement: equipment procurement is the most important part of setting up the production line. Therefore, it plays a decisive role in obtaining the final result. Among the main equipment for plastic rope production, we can mention incubator, extruder and coiler.

- The second step of creating a production line: Creating a production line is one of the other important measures for setting up a production line. An important principle that you should pay attention to when creating a product line is training and expertise in how to establish it. It should be noted that the arrangement and placement of the extruder, conveyors and coiler plays an effective role in the effective operation of the production line. The arrangement of all these equipments should be in such a way that it does not occupy a lot of space so that the equipments and machines occupy the least possible space. It is natural that the less space used in the production line, the costs related to the purchase or rental of the production line will be reduced to a great extent.

- The third step of setting up the production line: At this stage, the owner of the production line must present a plan and idea that is comprehensive and take action to provide the necessary raw materials, including polypropylene and polyethylene, each of which has a specific use in production.

Necessary tools and equipment to set up a rope production line

Fiber production equipment: This equipment consists of cold water tank, hot water tank, extruder, stretching system and winder. After passing through the production process, the fibers are wrapped around the spool and finally transferred to the machine. There are different types of weaving machines, because the plastic rope is made in different diameters.

final word

Currently, rope is one of the most used products and has many consumers in different fields. In this article, we talked about how to produce all kinds of rope and also how to set up its production line. I hope it was useful. Lavan Baft sells its produced ropes under the brand names Salik rope and Wave rope. You can contact the numbers 00982188040765 and 00982188219612 to get all kinds of ropes.